IOT & Realtime Data Presentation

Infrastructure and Design

The Industrial Automation Monitoring System is built on a scalable and efficient architecture, ensuring seamless data collection, storage, and visualization. The system leverages Programmable Logic Controllers (PLCs) to gather real-time sensor data, including temperature, pressure, and flow. This data is continuously transmitted and stored in either an InfluxDB time-series database or a MySQL database, ensuring structured and efficient data management.

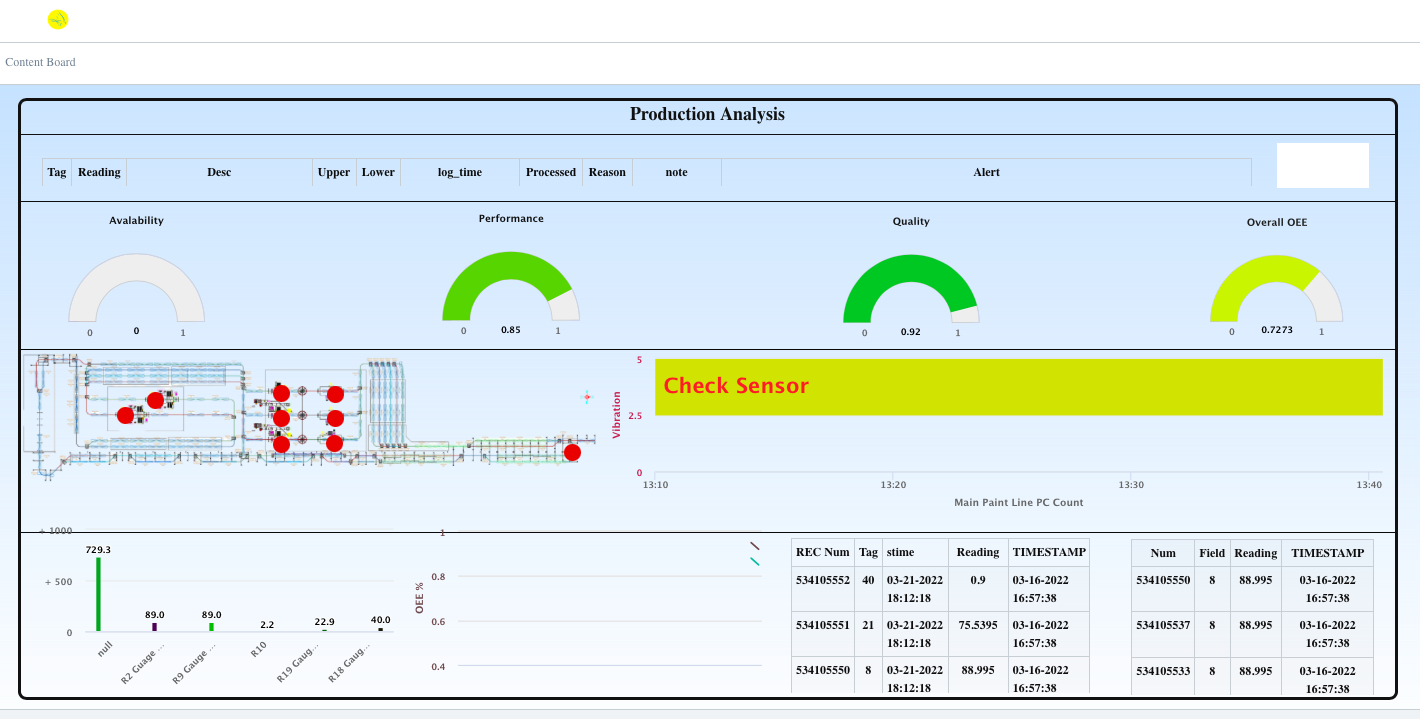

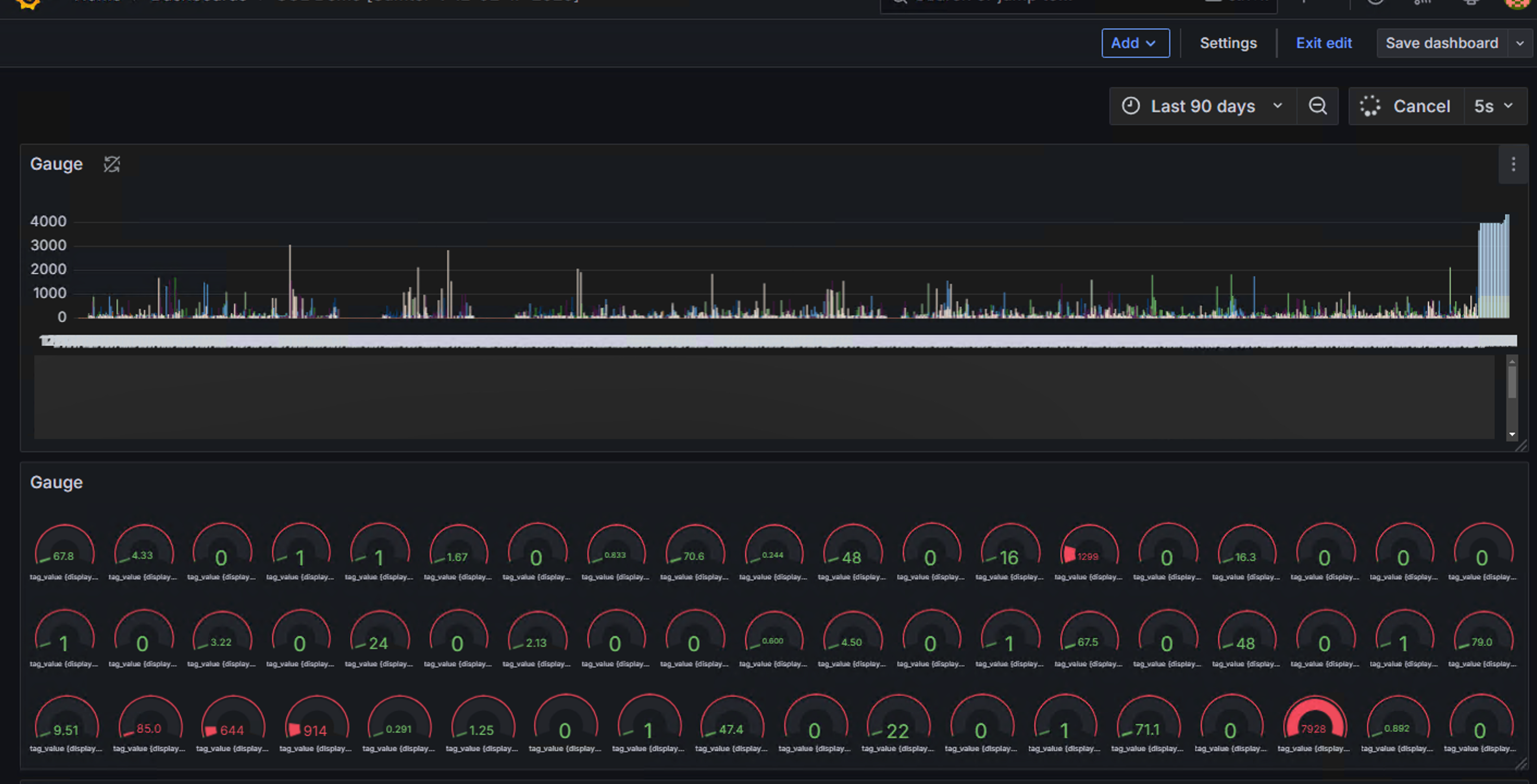

For real-time monitoring and analytics, the system utilizes an Angular-based web application, providing users with an intuitive dashboard for data visualization. Additionally, Grafana is integrated to enhance real-time data analysis, offering customizable dashboards and alerting mechanisms to track system performance and detect potential issues proactively. By combining PLCs, databases, and advanced visualization tools, this infrastructure ensures efficient monitoring, robust analytics, and data-driven decision-making, making it a reliable solution for industrial automation and performance optimization.

- Services: Business Automation and IOT

- Location: USA

Project Requirement

In this phase of the Industrial Automation Monitoring System, our focus is on building a scalable, real-time, and user-friendly solution for industrial data collection, monitoring, and analysis. The platform ensures seamless integration of PLCs, secure data storage, and advanced visualization capabilities to optimize operational efficiency and decision-making. By leveraging real-time processing, analytics, and compliance standards, it enhances reliability and performance in industrial environments.

-

Real-time Data Collection from PLC Sensors

-

Secure and Scalable Data Storage

-

Customizable Alerts & Notifications for Anomalies

-

Interactive Dashboard with Angular & Grafana for Live Monitoring

-

Role-Based Access Control (RBAC) for Data Security

-

Seamless Integration with Industrial IoT and Cloud Services

-

Automated Data Analysis & Performance Metrics

-

Testing, Deployment & Continuous Maintenance

Solution & Result

The Industrial Automation Monitoring System is a real-time and scalable solution designed to collect, store, and visualize industrial sensor data from PLC devices. By continuously gathering data from sensors such as temperature, pressure, and flow, the system ensures high accuracy and reliability in industrial operations. Secure data storage using InfluxDB and MySQL provides structured and time-series data management, while real-time dashboards in Angular and Grafana allow users to monitor system performance, detect anomalies, and make data-driven decisions.

To achieve this, our solution follows a comprehensive approach, integrating automated alerts, advanced analytics, and customizable dashboards. With continuous updates and seamless integration, it enhances data integrity, improves operational efficiency, and ensures proactive issue resolution, making it a robust and scalable monitoring solution for industrial environments.